Machine Shop Equipment List

Please review a selection of the equipment utilized by Future Test. While this list does not encompass all our equipment, it highlights our primary tools.

- Haas Vertical Mill (VF2) – Three axis CNC vertical mill, standard speed

- Haas Vertical Mill (VF 2SSYT) – Three axis CNC vertical mill, high speed, extra capacity

- Haas Vertical Mill (VF 2SS) – Three axis CNC vertical mill, high speed

- Haas Vertical Mill (VF 2SS) – Three axis CNC vertical mill, high speed

- Datron Vertical Mill (M8A) – Gantry style CNC mill, 60,000RPM spindle and 24”x36” vacuum chuck for intricate flat stock

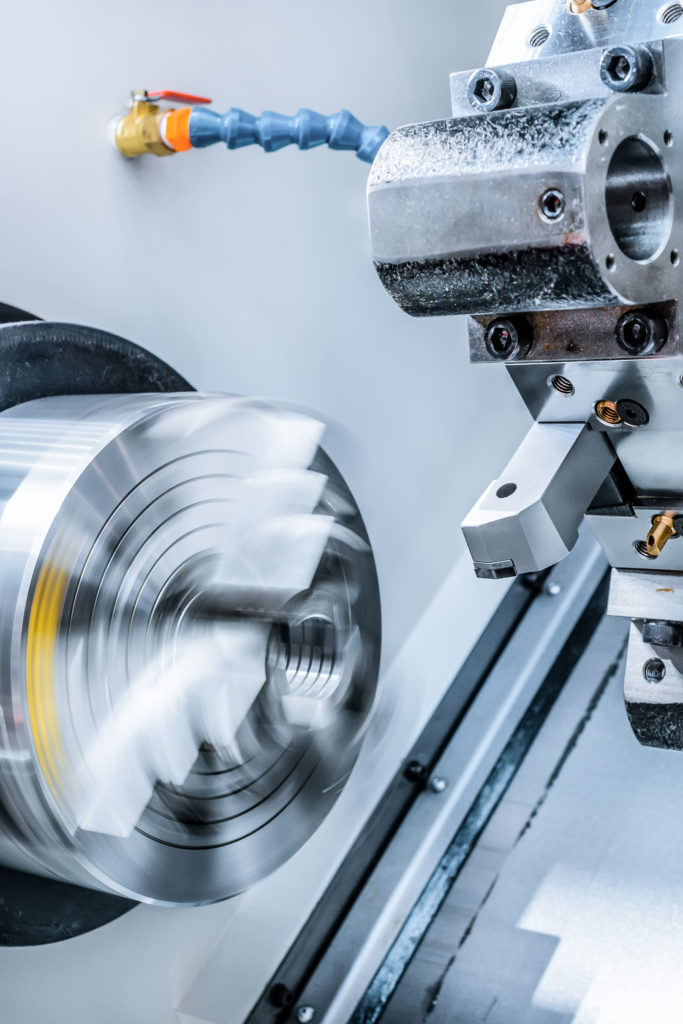

Lathes

- Somec Slantbed Lathe (Xcell) – Barfeed CNC lathe for small round parts

- Tsugami Swiss Turning Center (P03) – Barfeed small dia CNC lathe for high precision micro parts

- KSI Swiss Mill/Turn Lathe (SQX32) – Barfeed swiss style 17 axis CNC lathe for complex round parts cal mill, high speed

- Haas Lathe Turning Center (SL 20T) – Large two axis CNC lathe

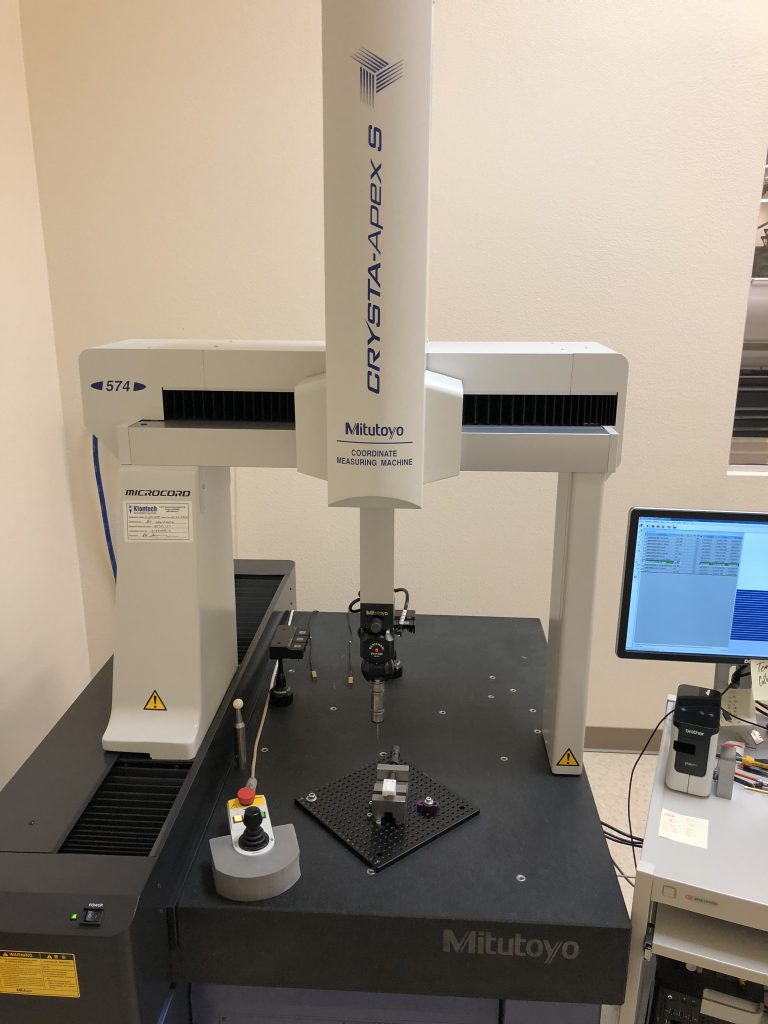

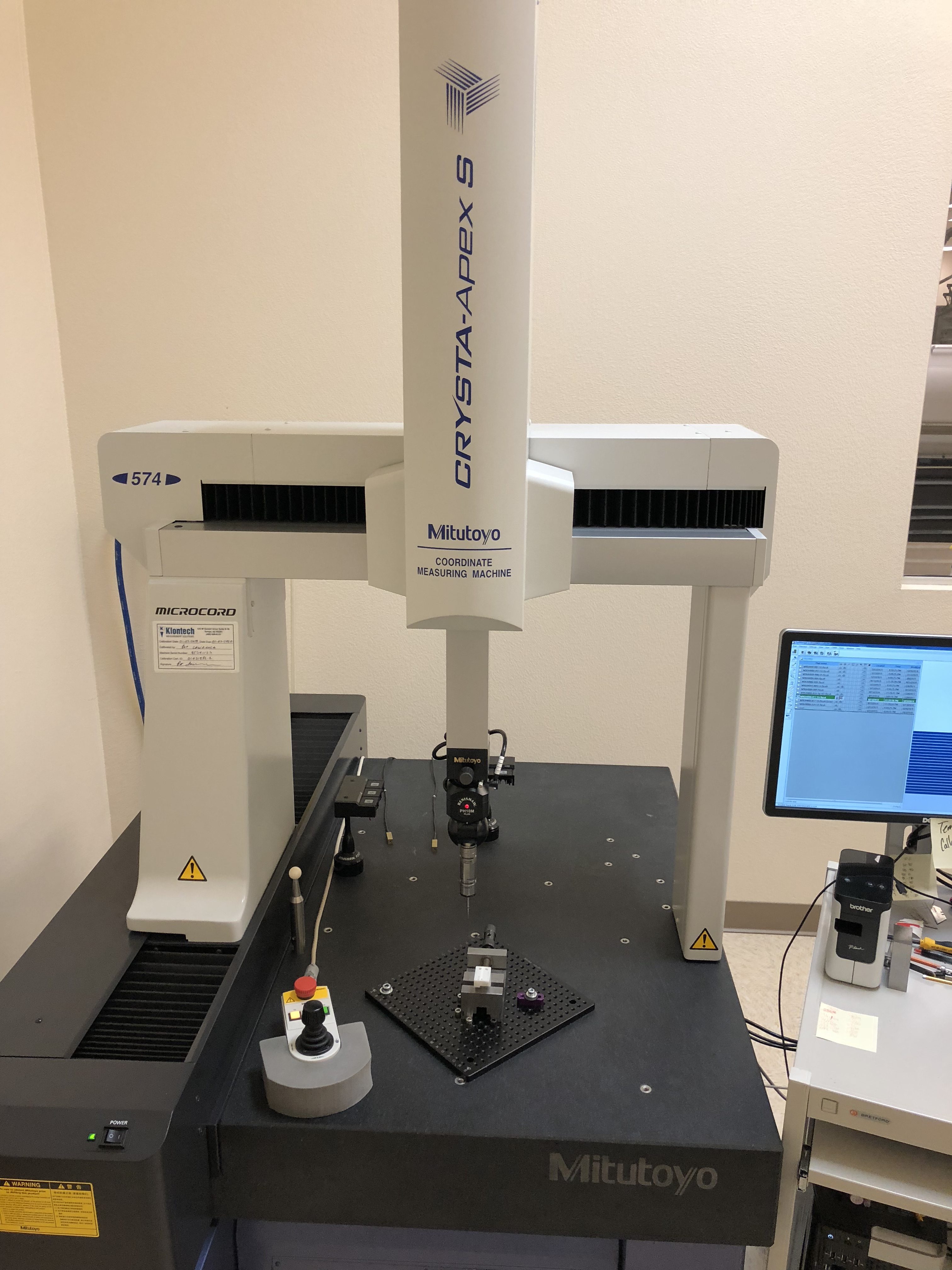

With today’s complex and precision mechanical parts, obtaining precise dimensional information is very important to confirm those parts are being made to specifications. We use a Mitutoyo Crysta-Apex 574 CMM (coordinate measuring machine) with a scanning probe capable of measuring to millionths of inches to validate parts.

This CMM allows us to manage and document quality control of machined parts as well as being useful for identifying machining issues that affect finished dimensions.

Built-in temperature probes allow this CMM to compensate for thermal effects even when measurements are taken under less than ideal conditions.

For consistently accurate and repeatable measurements, MCOSMOS software drives the CMM measurements effectively removing operator influences from all measurements.

- Keyence IM720 Series Optical Measuring Machine

- Starrett Surface Plate (24” x 36”) – Used for dimensional verification with height gauge

- Mitutoyo Optical Comparator (PH A14) – Used for optical dimension verification with height gauge

- Mitutoyo Coordinate Measuring Machine (Crysta Apex S574) – CNC driven CMM with a scanning probe, able to verify part features against a solid model

Other Manufacturing Support Tools

- Epilog Laser 50w CO2 (Fusion 13000 Laser System) – 36”x27” bed, for cutting plastics and engraving

- Epilog Laser 20w FiberMark (8000 Laser System) – 12”x24” bed, for cutting metal and micro engraving

- Heller Press Brake (PPB 4404) – Used to bend sheet metal

- Tennsmith Shear (LM510) – Used to cut large sheets of metal (for job prep)

- DoAll CNC Saw (DC 310 NC 11) – Used to cut stock (for job prep)

- Miller Welder (Millermatic 211) – MIG welder, for welding steel

- Eastwood Tig Welder (Tig 200) – TIG welder, for welding aluminum and small parts

- Rofin Micro Laser Welder (Performance) – CNC driven micro laser welder capable of .003” spot size

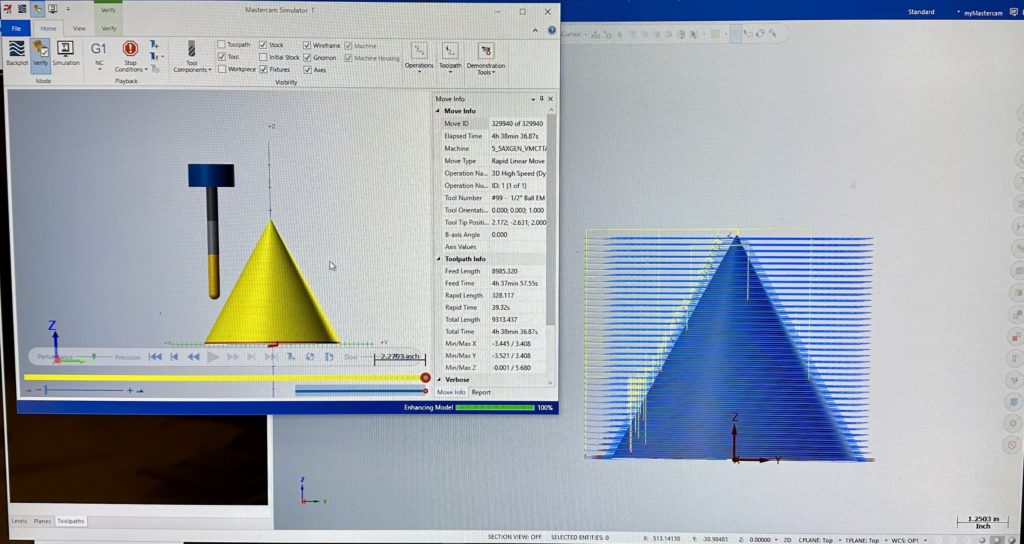

Mastercam Machining Software

We apply the latest CAM software to program efficient toolpaths for our CNC equipment.

Machine Services

We can quote your custom machining requirements. Please provide the following:

1. Dimensioned drawing

2. Solid model if available

3. Material, finish, tolerance

4. Any special requirements